We have in-house foundry with controlled heating systems for melting.

Vision & Mission

ISO 9001: 2015 Certified

Quality Policy

Why Choose Us

Maintain standards of Quality,

Perfection and Innovation

sections & aesthetic

look.

traceability &

accurate weights.

promise.

Easy Installation.

History of Industrial Experience

Why Choose Us

Maintain standards of Quality,

Perfection and Innovation

sections & aesthetic

look.

traceability &

accurate weights.

promise.

Easy Installation.

History of Industrial Experience

Strength Of Prinzaa

In-house Die Maintenance with necessary tools & facilities.

Having highly skilled, motivated and disciplined team WORK.

Minimize cost by reducing wastes, re-work and scrap

More than 1000 Dies available.

Proven Performance

Commitment – to do things in organized way and deliver in time for the outmost satisfaction of our customers.

Sales & Marketing

We are committed to producing high quality aluminium extrusions which meet all international standards and we work towards giving complete solution to our customers by supplying aluminium extrusions with value added services such as anodising, powder coating, fabrication etc.

Managing Directors Message

Technology

Performance ofsuch an up to date technology, we had set up our company proficient in the production of highly refined close-grained and oxide free logs, which as a result offer improved finish on the extruded sections.

Extended Services

Prinzaa has built a reputation as a trustworthy, quality exporter of aluminium extrusions and manufactured products. We are renowned for our consistency of supply and our ability to adapt to the needs of our customers. Supported by an experienced professional team, we are committed to providing innovative supply solutions to international markets.

Infrastructure / Plant & Machinery

Prinzaa Has Aluminium Extrusion Presses Installed With Latest Technology That Can Produce Extrusion Of 6000 Metric Tons Of Aluminium Per Annum. This Makes Prinzaa Able To Meet All Kinds Of Requirements Of Aluminium Work In Its Entirety.

Foundry/Billet Casting facility (Hot Top Casting)

We have in-house foundry with controlled heating systems formelting.

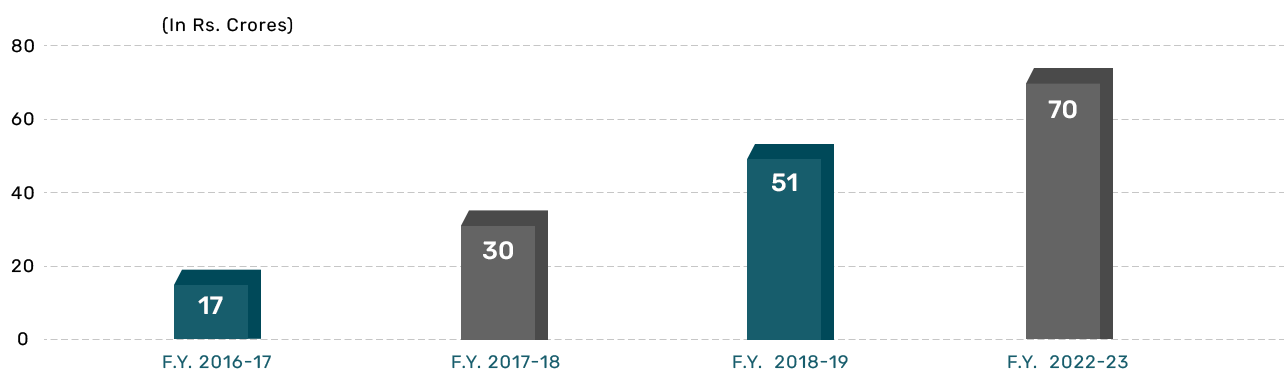

Turnover

The turnover of Prinzaa Aluminium (Prime Insulators Pvt Ltd) is above Rupees 70 Crores (8.6 million US $), whereas the turnover of Prime Insulators Group is a whooping Rupees 350 Crores (43 Million US $).

Research & Development

Our technical services and research team provides customised design solutions to suit individual company requirements. Our goal is to leverage our research and development capabilities to generate distinctive value for our customers through innovative design solutions that deliver improved performance, durability and employing processing techniques that reduce cost

Customer-Focused Innovation

Prinzaa specialises in the supply of precision aluminium extrusions and machining services to a broad spectrum of automotive and industrial industries.Our experience and exposure to global markets provide customers with the confidence that PRINZAA understand their needs in quality and on time delivery, making us a trusted supplier to specialised industry groups viz. Electrical & Electronics, Architectural, Industrial (Building and Construction), Automotive & Transport, Pharmaceuticals, Packaging, Aerospace, Defence, Solar, Renewable Energy, EPC (Transmission & Distribution), Ari Conditioning, Textile, Railways Etc.

Extrusion

Anodising

Turnover Chart